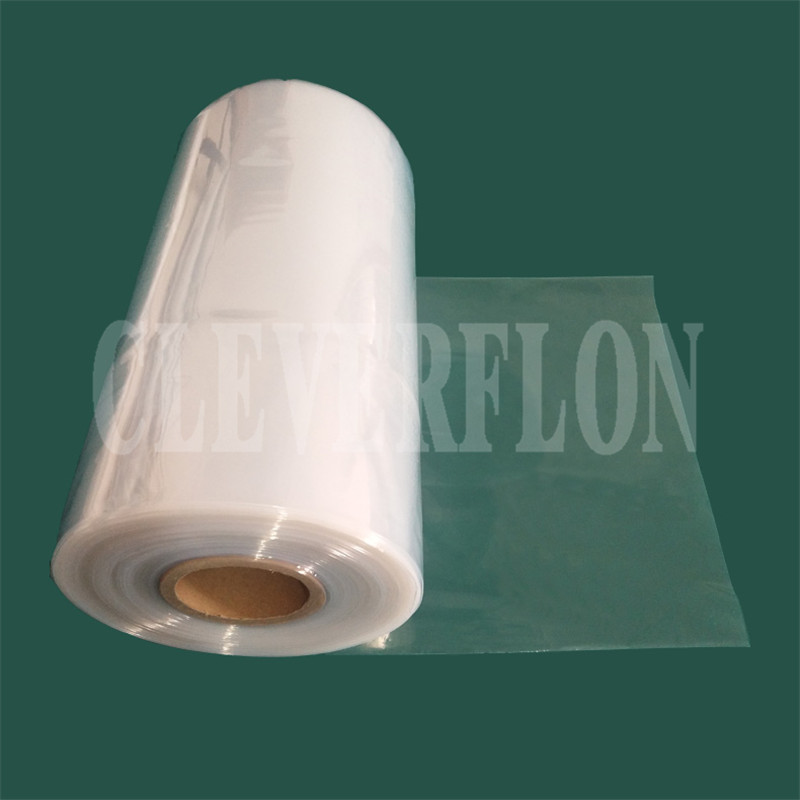

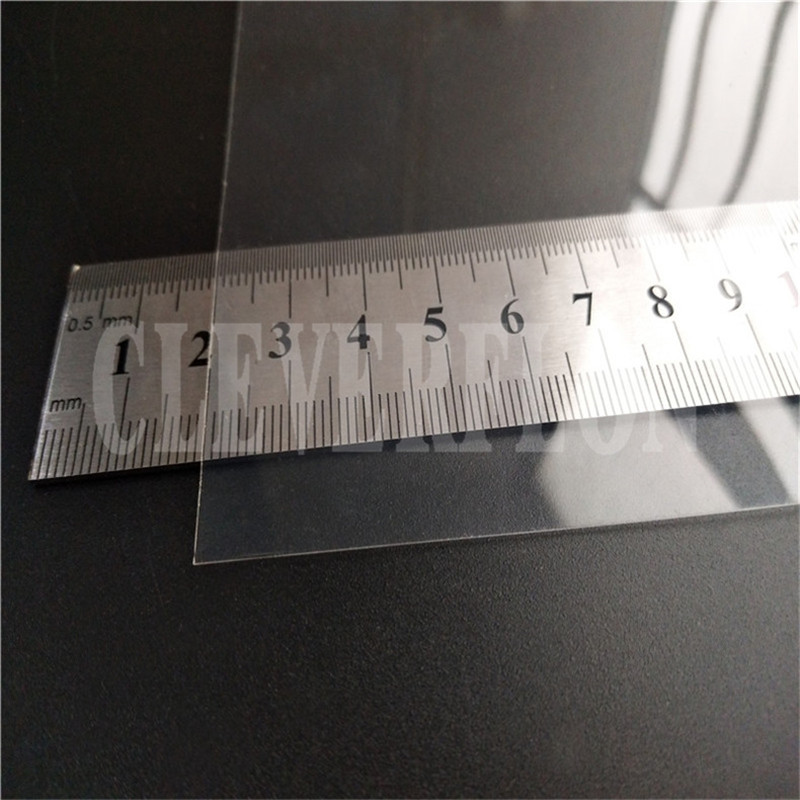

100micron thickness more than 95% light tansmittance FEP film

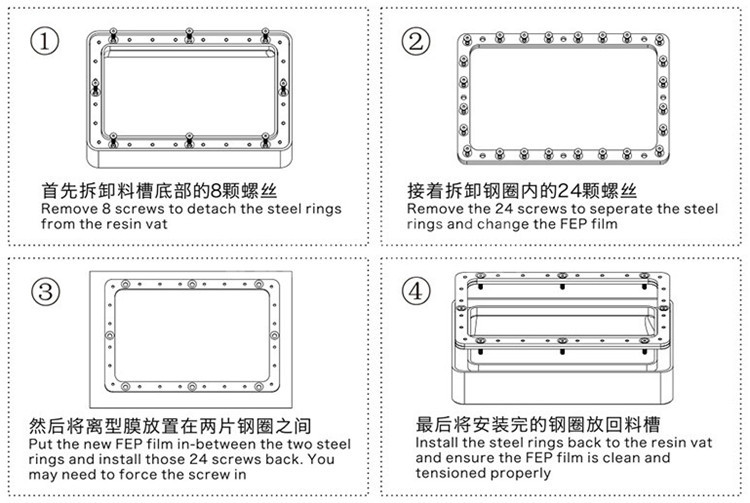

The steps of installing fep release film to the resin tank:

FEP film is made from fluorinated ethylene propylene (FEP) resin. FEP provides the chemical and thermal resistance to withstand aggressive environments, making it an excellent candidate for diaphragms, gaskets, protective linings, sample bags, and containers. Fabricated shapes and contours can be produced via heat sealing and thermoforming.The outstanding weatherability and optical properties of FEP film provide excellent performance in environmental growth chambers and solar collectors.

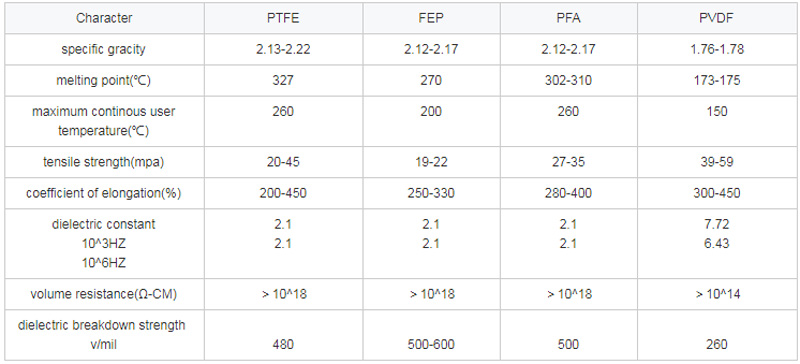

Data sheet of fluoropolymer products

Main features of FEP film:

1. Extremely good adhesion with F4(PTFE), good heatsealing.

Under melting point, it didn't have chemical reaction with other material.

Beyond melting point, it has good adhesion with F4 and metal

2. Wide operating temperature-85 ˇăC to 200 ˇăC;

3. Aging resistance, long life(more than 20 years);

4. Excellent resistance to solvents and chemicals;

5. Good flame resistance;

6. Extremely smooth surface;

7. Non-stick, non-toxic, water proof and oil proof,Water wrapping angle: ¦Č=114oC;

8. High transparency:

UV light and visiable light have good penetrating, compared with other plastic, it has the lowest refraction coefficient.

9. Electricity reliability, high insulation Under 60HZ60MHZ, dielectric constant is 2.1. Even if firing, and it will still insulate. Volume resistance > 10^18¦¸m Surface resistance > 2 X 10^13¦¸ Voltaic Arc >165 seconds insulation.