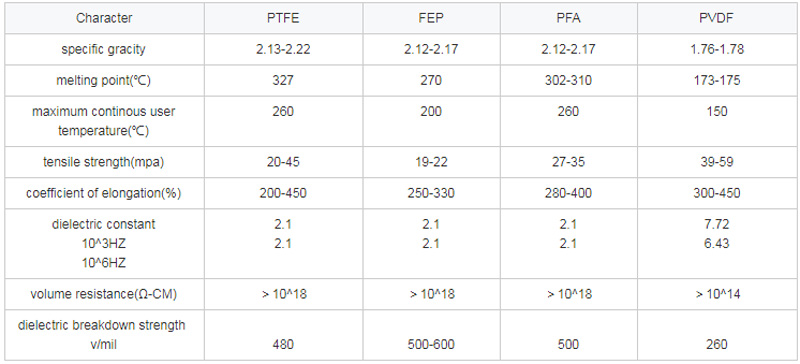

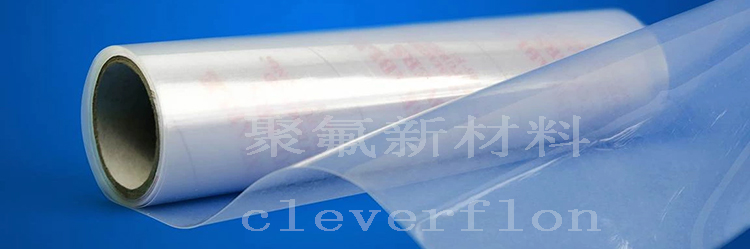

transparent PFA FEP F46 membrane for PTFE products welding

PFA fluoropolymer film is made from perfluoroalkoxy (PFA) resin. This film offers the highest continuous use temperature 260°C (500°F) of any melt-processable fluoropolymer film. In addition, PFA provides superior creep resistance at high temperatures, excellent low-temperature toughness, and exceptional flame resistance. With these superior attributes as well as enhanced flex life,PFA film can be a upgrade where FEP will not service the most demanding design hurdles.

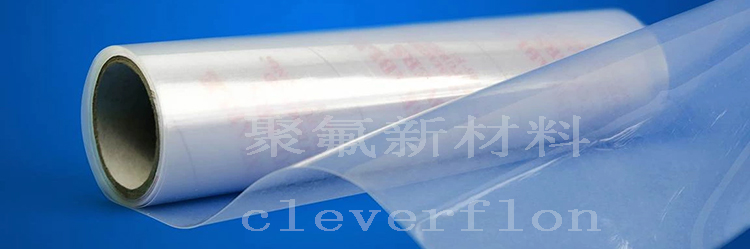

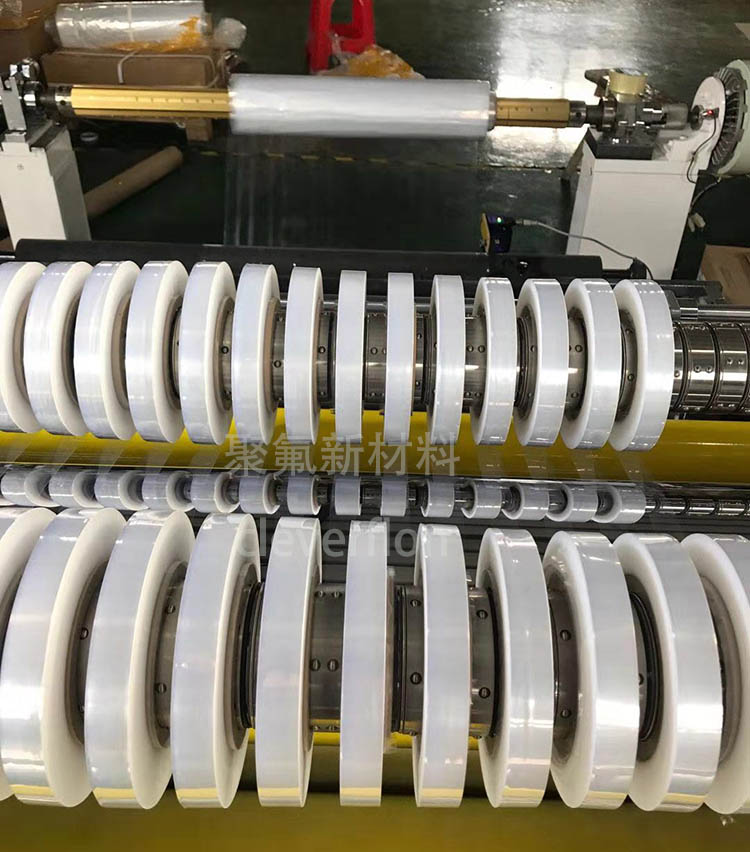

Thickness: 0.02~0.3mm

Width: 50~300mm or customized

Length: customized

Main features:

1. Extremely good adhesion with F4, good heatsealing

Under melting point, it didn't have chemical reaction with other material.

Beyond melting point, it has good adhesion with F4 and metal

2. High and low temperature resistance -85 ~ 260oC

3.Non-flammable, Not sticky, waterproof, oil proof

Water wrapping angle: θ=115oC

4. Electricity reliability, high insulation

Under 60HZ60MHZ, dielectric constant is 2.1. Even if firing, and it will still insulate.

Volume resistance > 10^18Ωm

Surface resistance > 2 X 10^13Ω

Voltaic Arc > 165 seconds insulation

5. High transparency

UV light and visiable light have good penetrating, compared with other

plastic, it has the lowest refraction coefficient

6. Weather resistance

Under ozone and sunshine for long time.

Use:

* Agglutinant

* F4 wax cloth belt, transmission belt combining adhibiting

* F4 copper board inner adhibiting

* Welding film

* Electroanalysis

* High temperature adhesive tape material

* Anti-corrosion lining

* Surface protecting material

* Non-metal compensator in thermo-eletric plant

* Flameproof electric machinery

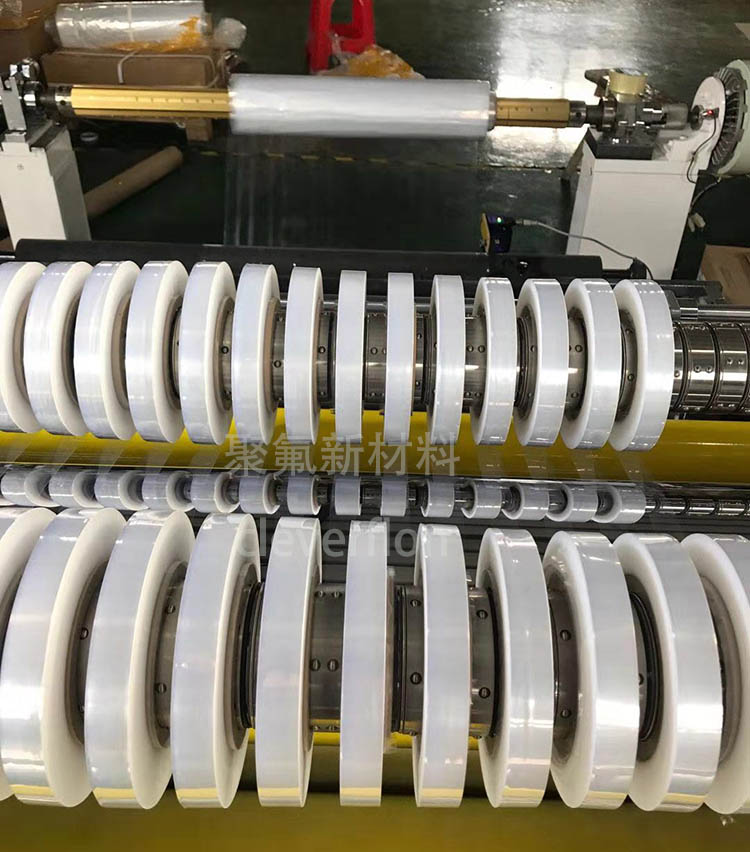

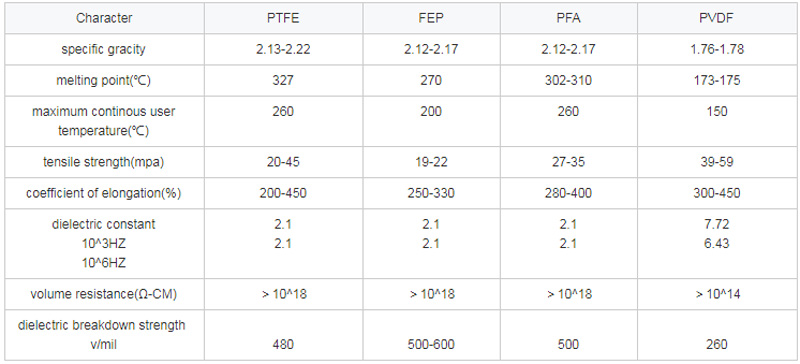

Data sheet of fluoropolymer products