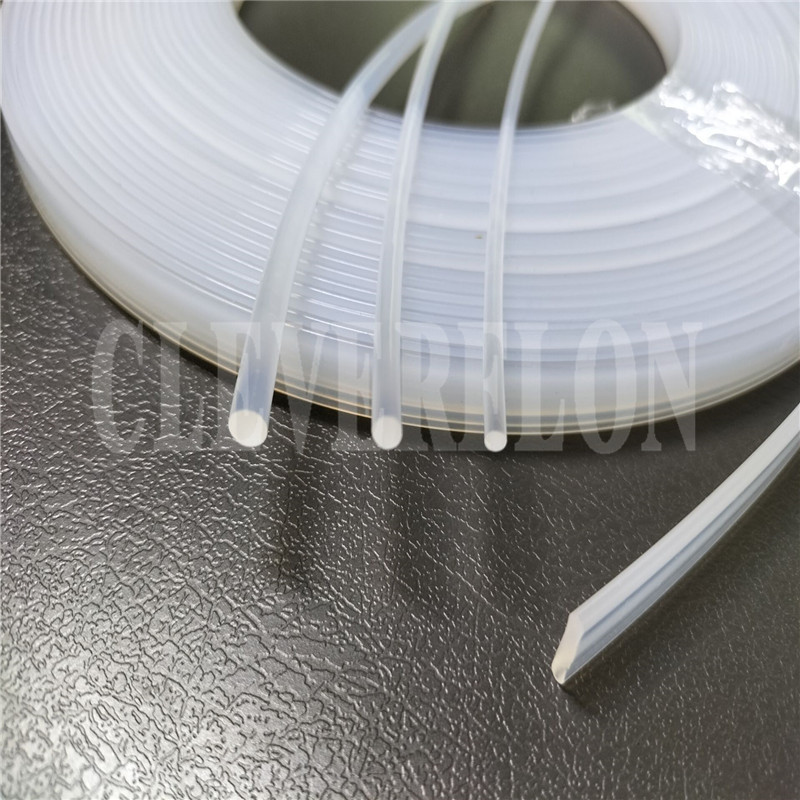

PFA Welding Rod for PTFE F4 products welding

The electrode by soluble polytetrafluoroethylene (PFA) resin after extrusion forming, excellent resistance to high and low temperature resistance,

high insulation, corrosion resistance, non-combustible and not sticky, it also has a hot melt sealing, weldability, suitable for big - 85 oC ~ 260 oC temperature range of excellent material.

PFA kept four fluorine excellent chemical stability, mechanical properties, electrical insulation self-lubrication,

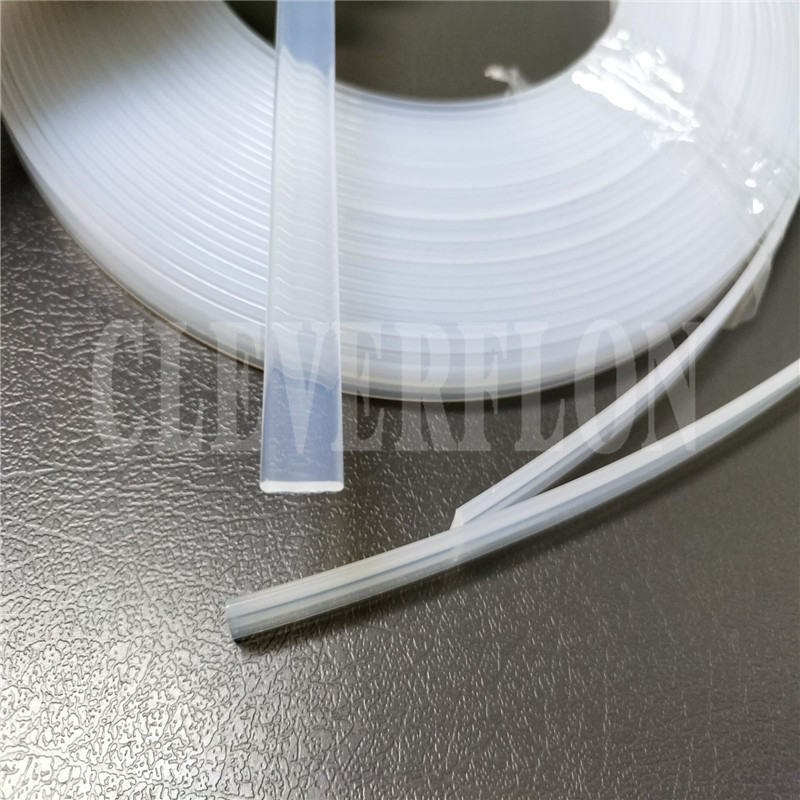

not sticky incombustible and aging resistance of its outstanding characteristic is the number of melt viscosity is lower than F4,

so the processing of its products is the common thermoplastic plastic molding method of high temperature stability performance is good,

high mechanical strength is higher than PTFE about two times, and PFA softer than ptfe film, the resistance performance is good, good cracking resistance.

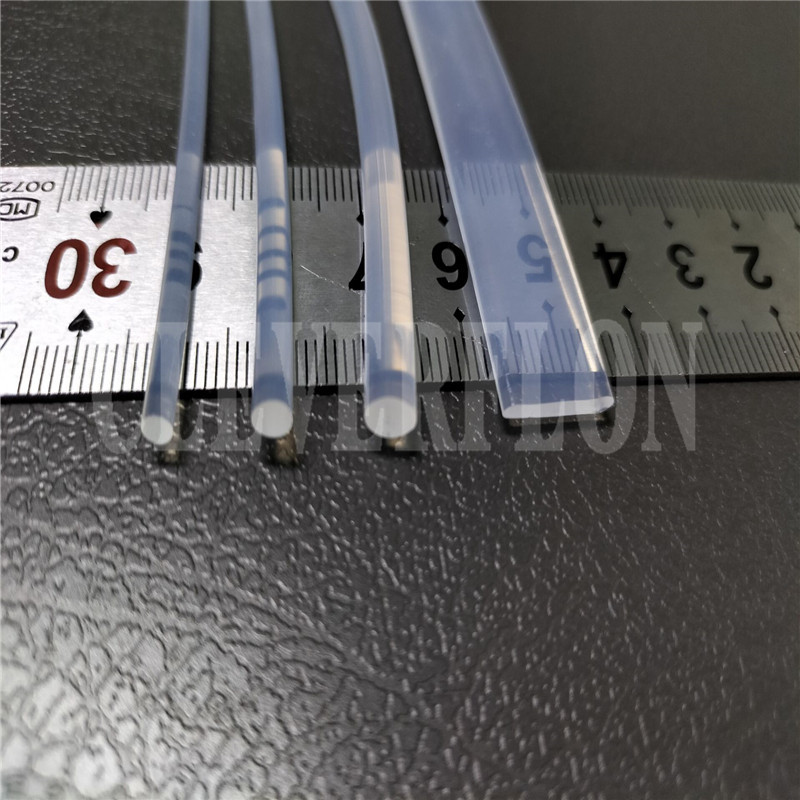

Welding is done by preheating the material with a hot air stream. The gun heats the air, but an air source must be provided by the gun.

The welding rod is also preheated by the gun. When the materials are ready to be welded, the gun tip is simply run along the area where the weld is desired, feeding the welding rod manually in the process.

The welding technique for PFA is similar to that used for polypropylene. However, the fusing temperature is much higher and added measures must be taken to ensure adequate ventilation.