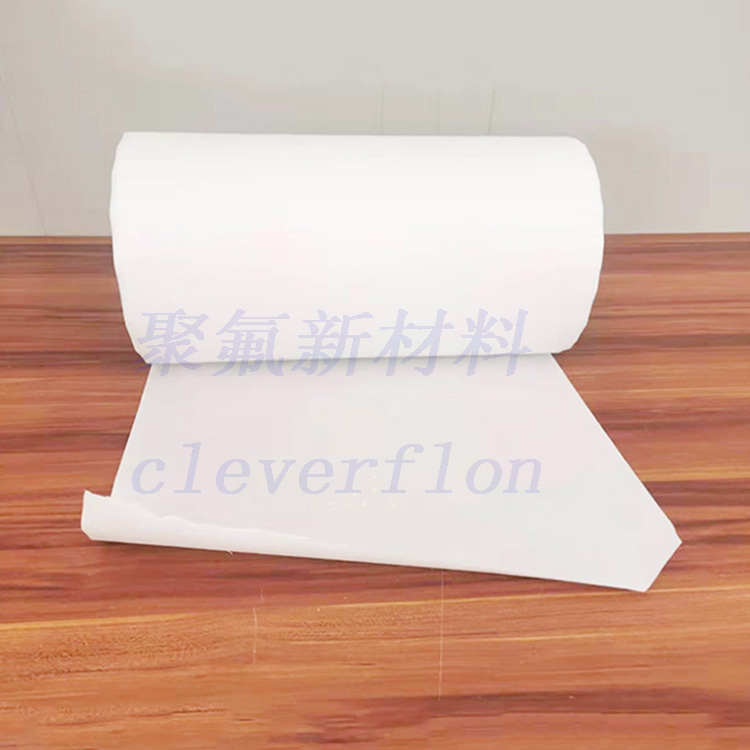

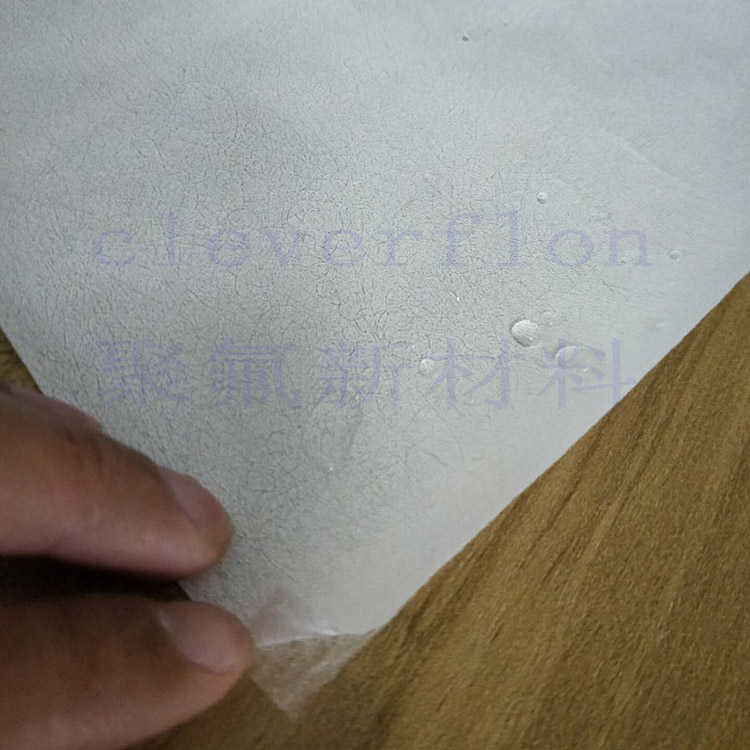

China Factory Micopore Eptfe PP Hydrophobic Composite Film for Air Filtration

| Product No. |

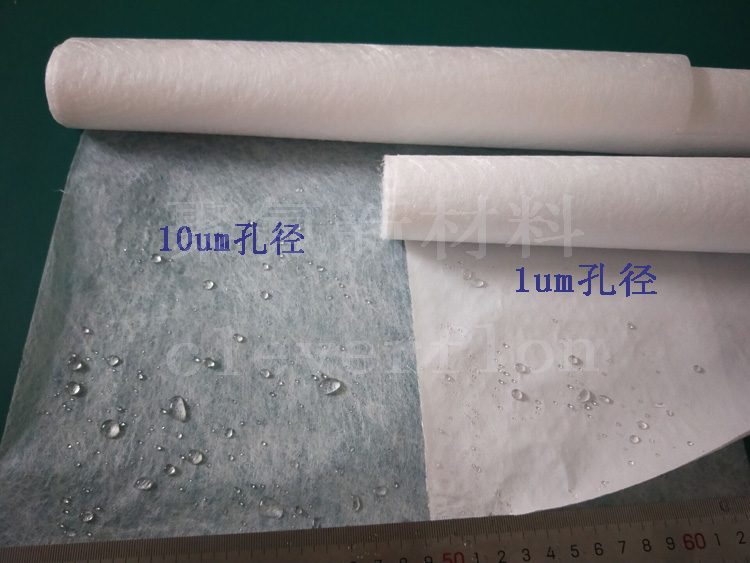

Pore size (um) |

Ethanol anhydrous

initial bubble pressure(Mpa)

|

Air flux

m3/m2.hr@0.01Mpa,25oC

|

Reinforce ment |

Thickness

(um)

|

| ZYMSF-01 | 0.1 | ≥0.14-0.16 | ≥400 | PP non-woven fabric | 160-300 |

| ZYMSF-022 | 0.22 | ≥0.10-0.12 | ≥600 | PP non-woven fabric | 160-300 |

| ZYMSF-022G | 0.22 | ≥0.11-0.13 | ≥700 | PP non-woven fabric | 160-300 |

| ZYMSF-045 | 0.45 | ≥0.08-0.1 | ≥800 | PP non-woven fabric | 160-300 |

| ZYMSF- 1 | 1 | ≥0.04-0.06 | ≥1000 | PP non-woven fabric | 160-300 |

| ZYMSC-3 | 3 | ≥0.02 | ≥1400 | PP non-woven fabric | 160-300 |

| ZYMSF- 5 | 5 | ≥0.007 | ≥1600 | PP non-woven fabric | 160-300 |

| ZYMSF-10 | 10 | N/A | ≥2200 | PP non-woven fabric | 160-300 |

| the above data on initial bubble pressure and air flux is typical,thickness is dependent on base materials | |||||

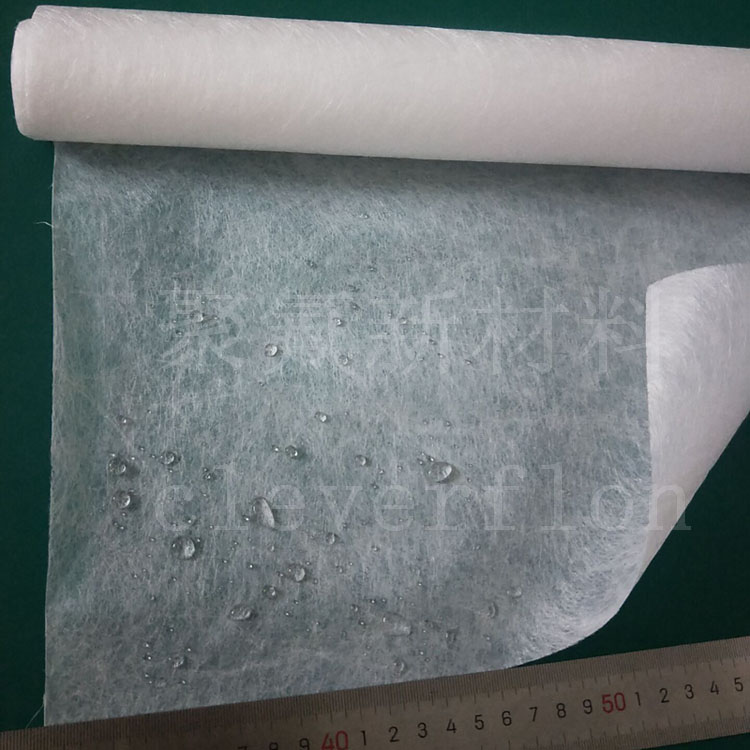

high temperature bonding technology. The reinforcements are easily folded with high chemical compatibility.

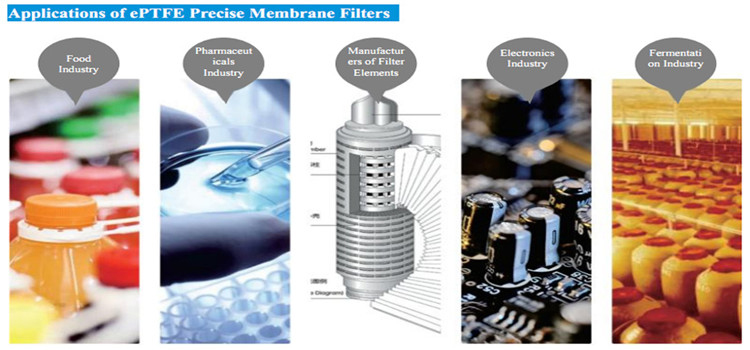

Typical Applications

1. Sterilize and filter compressed air;

2. Filter fermented air terminals in antibiotic and biological projects;

3. Sterilize and filter air at vents of tanks, containers and cartons;

4. Filter air of sterile packages.

ePTFE micropore filter membrane and various ePTFE compound materials have been widely applied in different fields, including electronics, micro-electronics, medicine, liquor-making, food industry, biological, engineering, petroleum chemistry, industrial wastewater treatment, seawater pretreatment and laboratories.