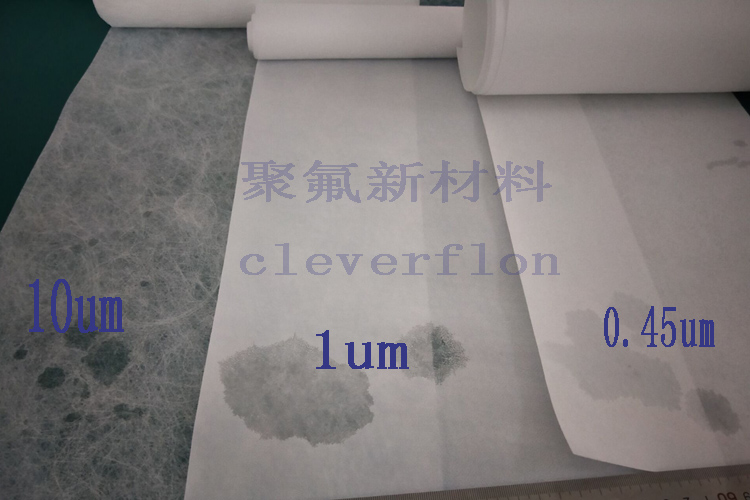

0.1 Um~10 Um Aperture Hydrophilic Eptfe Porous Membrane for Water Treatment

| Product No. |

Pore size (um) |

Ethanol anhydrous

initial bubble pressure(Mpa)

|

water flux

m3/m2.hr@0.02Mpa,25oC

|

Reinforce ment |

Thickness

(um)

|

| ZYMQF-01 | 0.1 | ≥0.14-0.16 | ≥2.5 | PP non-woven fabric | 160-300 |

| ZYMQF-022 | 0.22 | ≥0.10-0.12 | ≥3.5 | PP non-woven fabric | 160-300 |

| ZYMQF-045 | 0.45 | ≥0.08-0.1 | ≥5 | PP non-woven fabric | 160-300 |

| ZYMQF- 1 | 1 | ≥0.04-0.06 | ≥6 | PP non-woven fabric | 160-300 |

| ZYMQC-3 | 3 | ≥0.02 | ≥8 | PP non-woven fabric | 160-300 |

| ZYMQF- 5 | 5 | ≥0.007 | ≥10 | PP non-woven fabric | 160-300 |

| ZYMQF-10 | 10 | N/A | ≥15 | PP non-woven fabric | 160-300 |

| the above data on initial bubble pressure and water flux is typical,thickness is dependent on base materials | |||||

The reinforcements are easily folded with high chemical compatibility.

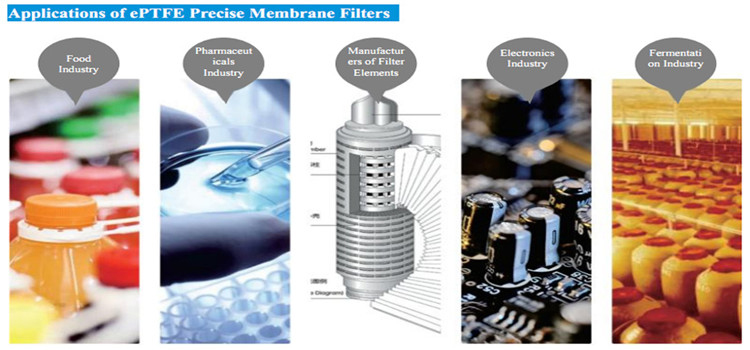

Typical Applications

1. Clarify, sterilize and filter liquid strong oxidants;

2. Clarify, sterilize and filter highly corrosive liquids;

3. Clarify, sterilize and filter highly protic organic solvents;

ePTFE micropore filter membrane and various ePTFE compound materials have been widely applied in different fields, including electronics, micro-electronics, medicine, liquor-making, food industry, biological, engineering, petroleum chemistry, industrial wastewater treatment, seawater pretreatment and laboratories.