Mbr Waste Water Treatment Membrane Eptfe PVDF Hydrophilic Filter Membrane

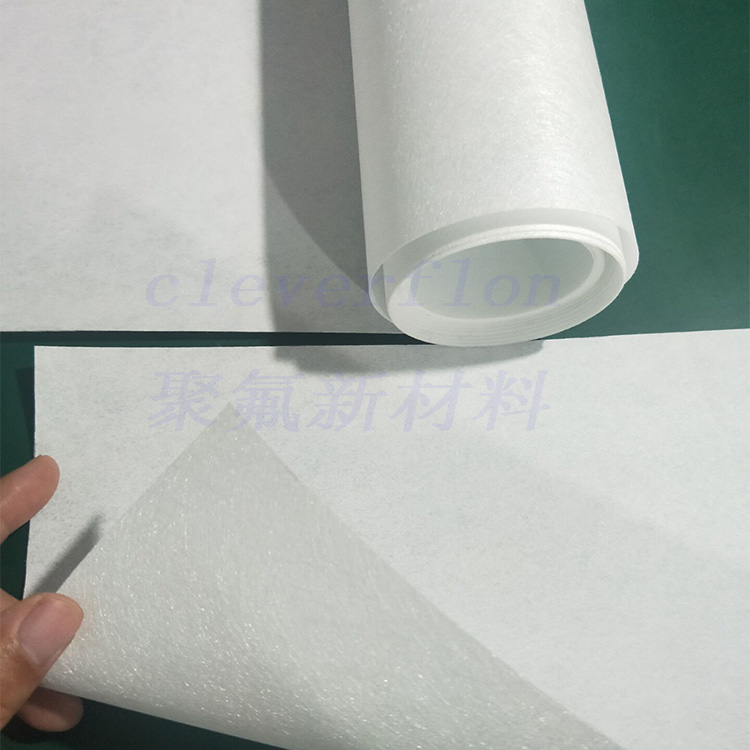

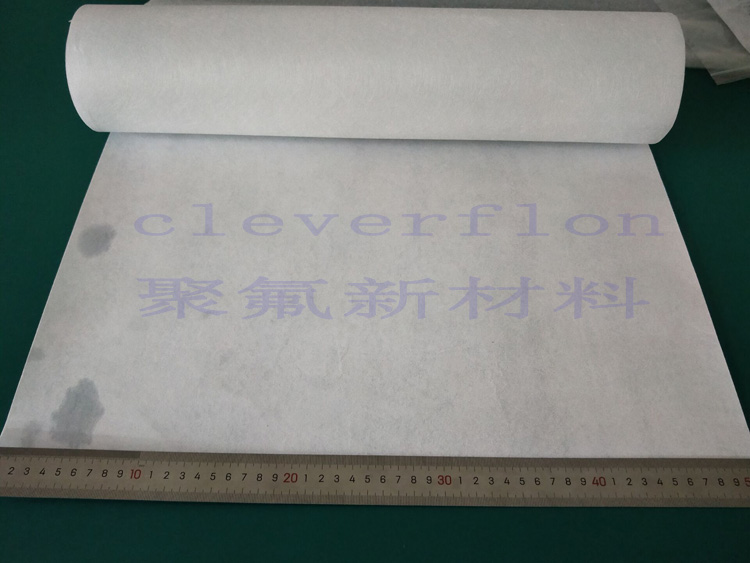

Normal width 260mm,520mm (max width 1600mm) or customized

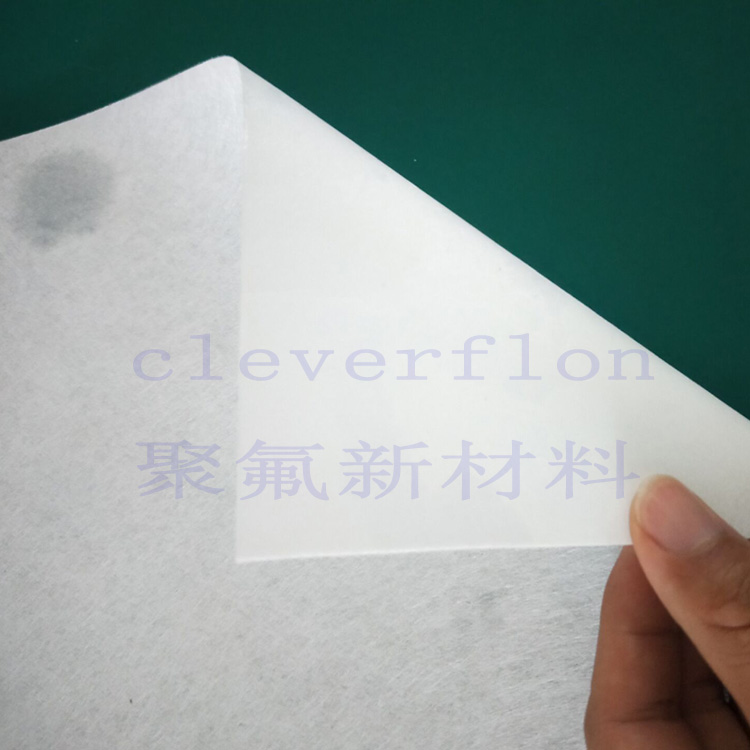

Type: flat rolled membranes

Technical Parameters

Product No.

Pore size

(um)

Reinforce

ment

Thickness

ZYMQF-01B

0.1

≥0.14-0.16

≥300

PET

200-450

ZYMQF-022B

0.22

≥0.10-0.12

≥500

PET

200-450

ZYMQF-045B

0.45

≥0.08-0.1

≥700

PET

200-450

ZYMQF- 1B

1

≥0.03-0.05

≥900

PET

200-450

the above data on initial bubble pressure and pure water flux is typical, the thickness is dependent on base materials

Product strengths

Compared with PVDF filter membrane, ePTFE micro-pore membranes have more uniform PTFE pores with

higher poroxity and higher water flux. In addition, the surface friction coefficient of ePTFE is intrinsically extremely

low, so MBR membrane elements made of ePTFE are more contamination resistant. Conventional PVDF

membranes produce much high-concentration refractory wastewater during their preparation.

This is also a major bottleneck that hinders promotion of PVDF membranes. PTFEmembranes are produced with

the most advanced dual-direction stretching and pore formation technologies. Their production process is more

environment-friendly, so PTFE membranes of higher market value for application.

Processing

The filtration materials are produced by laminating ePTFE micro pore membrane with PET with

high temperature bonding technology. The laminated membranes of reinforcements are quite flat and corrosion

resistant with high mechanical strength.